| Requirements | Cage roller | Double cage roller | Knife ring roller | Cutting packer roller |

| Consolidation | o | o | + | ++ |

| Damp conditions | o | o | o | ++ |

| Dry conditions | ++ | ++ | ++ | ++ |

| Crumbling effect | + | ++ | ++ | ++ |

| Load capacity | + | ++ | + | ++ |

| Self-propulsion | ++ | ++ | + | ++ |

| Suitability for stones | + | o | – | ++ |

| Scraper | no | no | yes | yes |

| Tare weight in kg for 3 m working width | 325 | 520 | 420 | 595 |

| Diameter in mm | 540 | 540 | 540 | 550 |

| Requirements | ROTOPACK roller | Rubber packer roller | CONOROLL roller | TANDEM CONOROLL roller |

| Consolidation | – | ++ | + | ++ |

| Damp conditions | o | + | ++ | + |

| Dry conditions | + | ++ | ++ | ++ |

| Crumbling effect | ++ | ++ | ++ | ++ |

| Load capacity | + | ++ | + | ++ |

| Self-propulsion | ++ | + | + | ++ |

| Suitability for stones | – | o | ++ | ++ |

| Scraper | no | yes | yes | no |

| Tare weight in kg for 3 m working width | 400 | 560 | 430 | 685 |

| Diameter in mm | 545 | 590 | 540 | 560 |

++ highly suitable

+ very suitable

o suitable

– not suitable

Cage roller

Cage roller

The ideal roller for dealing with dry, non-sticky soils. The roller is fitted with strong bars for optimal compression.

Diameter 540 mm, 11 bars.

Diameter 660 mm, 12 bars.

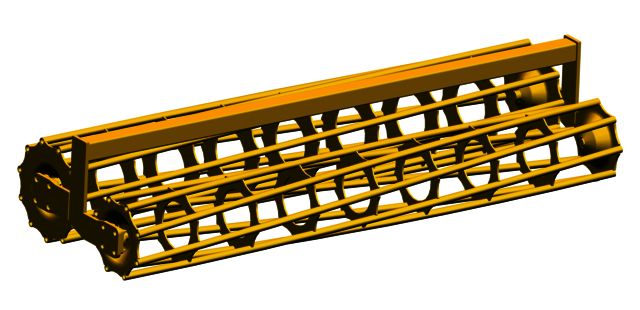

Double cage roller

Double cage roller

The double cage roller is fitted with two different diameter rollers (540 mm front and 420 mm rear). The pendular function ensures optimum ground tracking and perfect tilth.

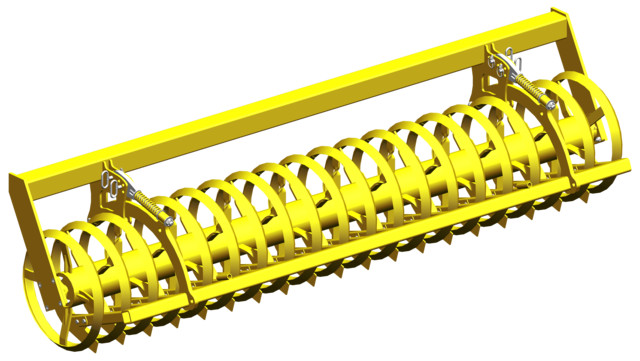

Knife ring roller

Knife ring roller

The advantages of the knife ring roller with a diameter of 540 mm include enhanced tilth and consolidation by means of wedge-shaped rings. The knives between the rings break up clods and keep the rings clean. Compression in strips has the advantage that water can be absorbed better. The right choice if you are working on dry and heavy soil with no rocks or stones.

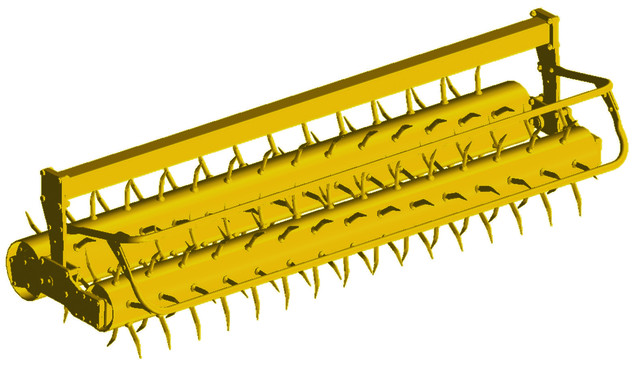

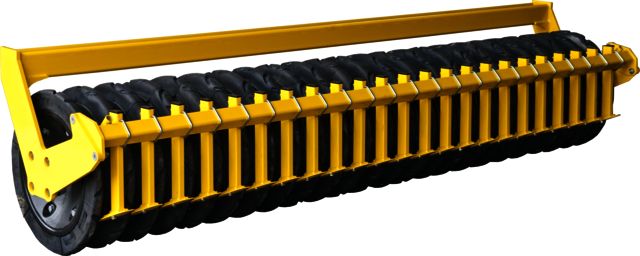

Pack ring roller

Pack ring roller

The packer rings, which are enclosed, have a diameter of 550 mm. eight rings per metre of working width. The roller leaves consolidated ridges, promoting drainage and soil respiration. This is the ideal roller on stony, damp ground with large quantities of organic matter. The scrapers are coated for an extended working life.

Rotopack roller

Rotopack roller

Rotopack rollers mix particularly intensively – for light to heavy, nonsticky soils. Harvest residues remain on the surface of the soil and protect your soil against drying out. Working width 3.0 m.

Rubber packer roller

Rubber packer roller

The perfect roller for widely varied soil conditions. Especially for use with trailed implements where the load-bearing capacity of other rollers is near the limit. A diameter of 590 mm and the special profiling allows the soil to be compacted in rows. The scrapers are coated for an extended working life.

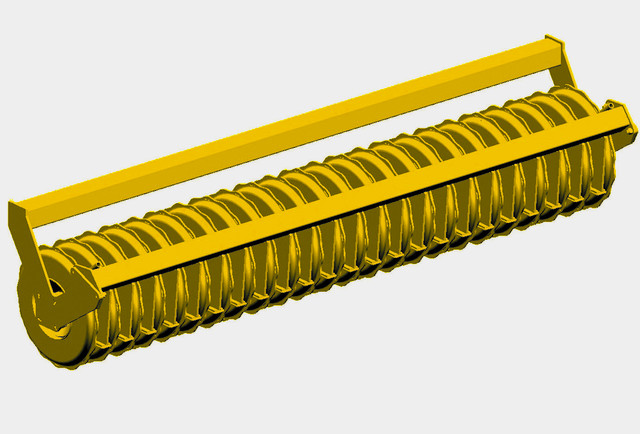

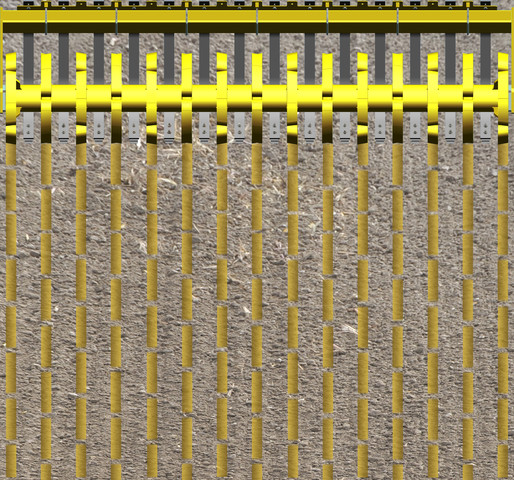

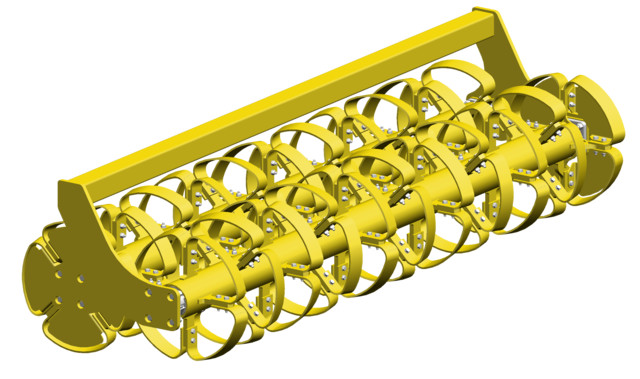

CONOROLL roller

CONOROLL

Roller print CONOROLL

This roller consists of rings with a diameter of 540 mm. Each ring is made up of four conical segments that are offset to the left and right. The result is a slot with alternate indentations on either side. When rainwater seeps into these indentations, they prevent it from flowing away. Erosion caused by rainfall is minimised thanks to the optimum structure created on the soil surface. The loose soil between the rings ensures good drainage. The gap between each ring is 15 cm. Spring-mounted scrapers are located in between. These promote the formation of a fine tilth while keeping the space between the rings clean. The load-bearing capacity of the CONOROLL is limited on very light soil. This is an ideal roller for medium to heavy soils. The side segments are covered. This guarantees trouble-free operation in harvest residues and stones.

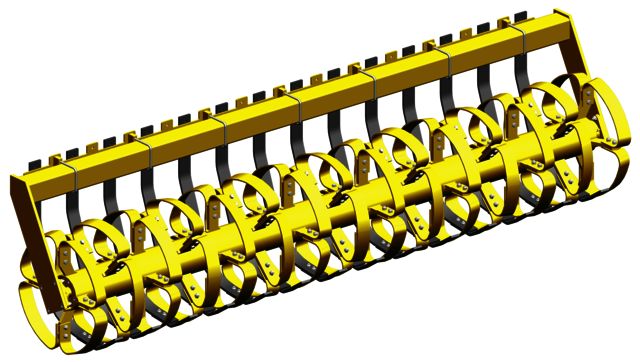

Tandem CONOROLL roller

Tandem CONOROLL roller

The tandem CONOROLL consists of two rollers with bar thickness of 8 mm. The diameter of the rings is 560 mm. Ideally suited to trailed TERRADISC machines.

The rollers overlap each other and each has a footprint equal to 50 % of the working width. This is especially well suited to light soil.

- The inclination of the roller can be quickly adjusted using a lock pin to allow for the working depth and operating conditions.

- No scrapers required; rollers self-clean effectively.

- Raised on rear roller at headlands, so there are no problems reversing the machine.

- Side-mounted edging boards that can pivot guarantee smooth operation in harvest residues and stony areas