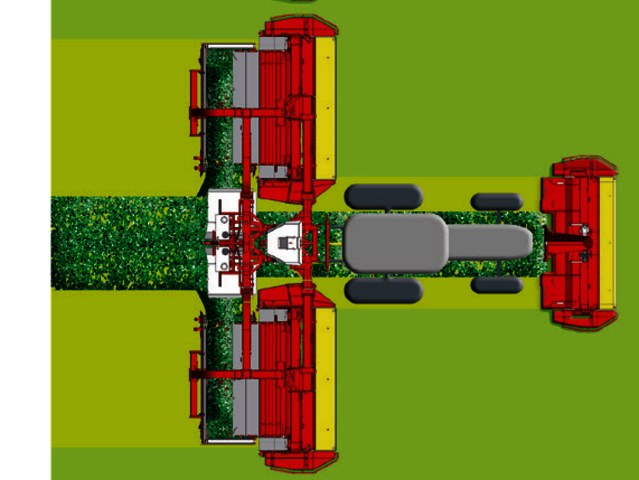

Raising the cross conveyor belts and narrowing the swath doors places three compact individual swaths.

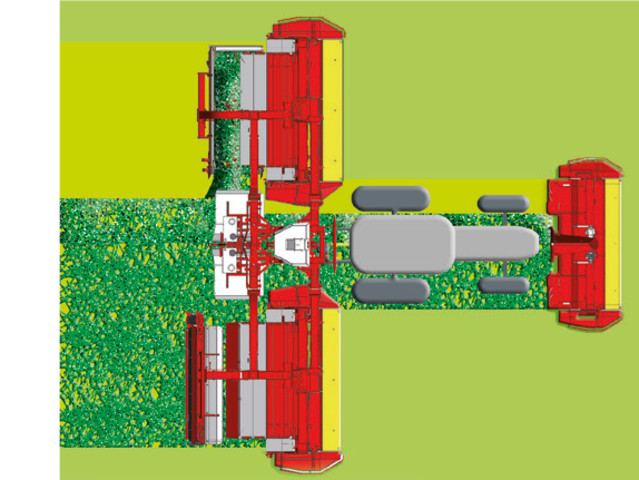

Wide spread placement

Wide spread placement

With the swath doors open, guide plates direct the flow of forage across the whole mowed width. The forage is deposited in a uniform and airy blanket.

Three swaths in one

Three swaths in one

The conveyor belts place the three swaths into one large central swath.

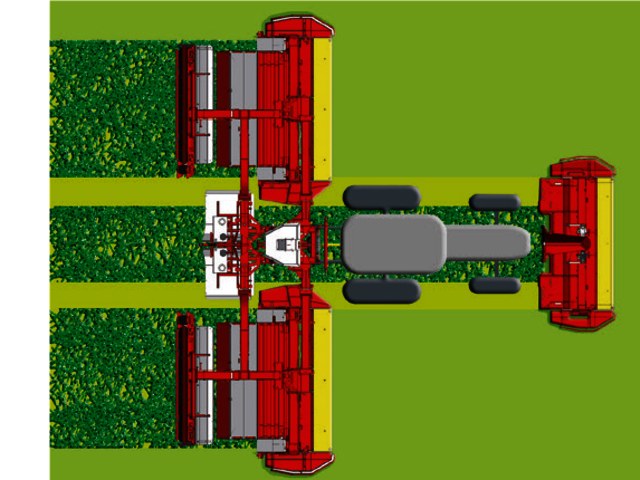

Wide swath placement

Wide swath placement

Save costs with combined wide swath placement

With the conveyor belts lifted individually, up to 40% raking work can be saved with a large TOP rake.

Maximum flexibility with cross conveyor belts

Swath merging conveyor belts

High output and maximum flexibility thanks to variable width forage placement are offered by the mower combinations NOVACAT X8 COLLECTOR with a fixed working width of 27.23′ / 8.30 m.

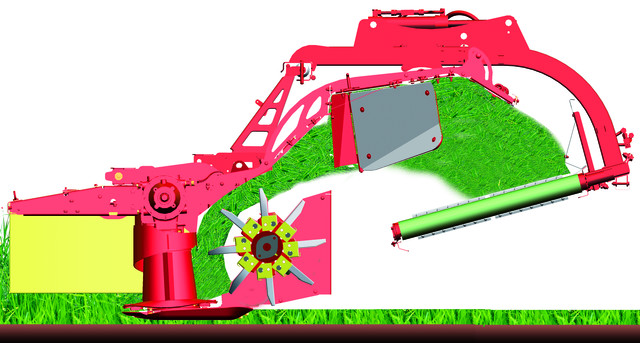

EXTRA DRY tine conditioner

EXTRA DRY tine conditioner

The steel tines are arranged in a spiral configuration to deliver a constant flow of forage to the conveyor belts.

RCB roller conditioner

RCB roller conditioner

The profiled rollers condition the forage and the additional accelerator roller propels it reliably onto the cross conveyor belts.

NOVACAT X8

The conveyor belts are equipped with their own on-board hydraulics. The perfect combination for tractors with a hydraulic flow rate below 80 l and under 200 bar. Continuously-variable belt speed control and additional accelerator rollers are available as an option. It only takes a few minutes to remove the conveyor belts and park them on their own supports.